METRICAL Software for Metallurgical Analysis

Specifications

- Metallurgical & materials analysis software in accordance with ISO and ASTM standards.

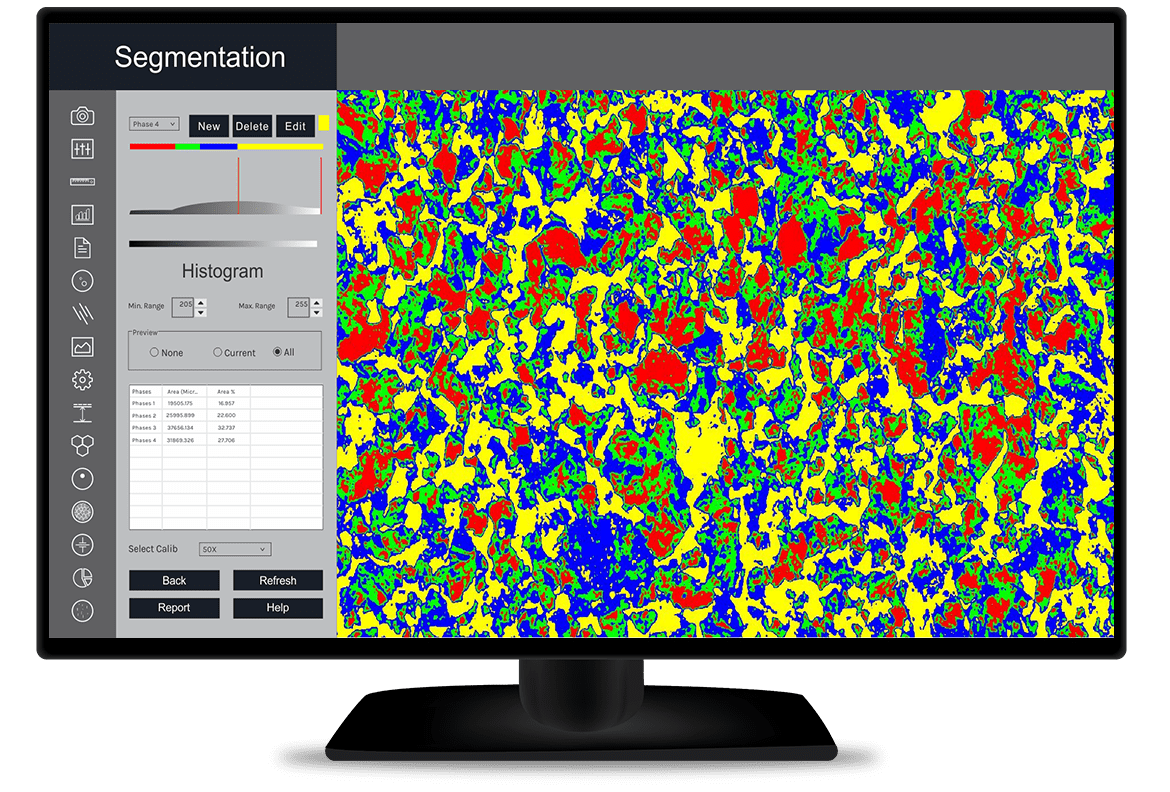

- Includes modules for Grain Size, Porosity, Segmentation, Decarburization, SG Iron / Nodularity, Gray Iron, Carbide banding, etc.

- Compatible with all Excelis™, Excelis™ 4K, and Lumenera Cameras. (Not compatible with Excelis™ Lite cameras.)

- Use with any brand of microscope.

- Windows operating system only.

Standard Specifications

METRICAL image analysis software is specific to metallurgical applications.

- METRICAL software is designed for Metallurgists, laboratory technicians, and R & D engineers who need improved solutions for quality control and product development.

- METRICAL follows strict ISO & ASTM technical standards.

- Work with multiple image formats including BMP, TIFF, GIF, JPEG, etc.

- Supports USB 2.0 & USB 3.0 cameras, and TWAIN input devices.

- This exceptional software produces as much as 80% more picture points in image window than competitive software’s.

- The image processing technique will streamline image capture, measurement and enhancement, while improving

the accuracy of your results. - Live measurements saves time and money.